Sundyne's PPI® Line of Diaphragm Compressors for Environmentally Safe & Leak-Free Processing of Critical Gases

Sundyne’s PPI diaphragm compressors deliver non-contaminating gas compression, through a leak-tight mechanism with static seals that do not need to be purged or vented. A set of metallic diaphragms isolates the process media from the piston & piston rings to completely eliminate the risk of cross contamination. Sundyne’s PPI compressors present zero leakage threat to the atmosphere, providing an ideal solution for safely handling ultra-pure, corrosive and volatile gases.

All models can be built to meet API 618 standards where applicable to diaphragm compressors. These machines are available in a variety of flexible configurations and sizes, making them easily customizable to fit a wide range of applications in the Hydrogen processing, petrochemical, refining, electronic gas, specialty gas and poly-silicon production industries.

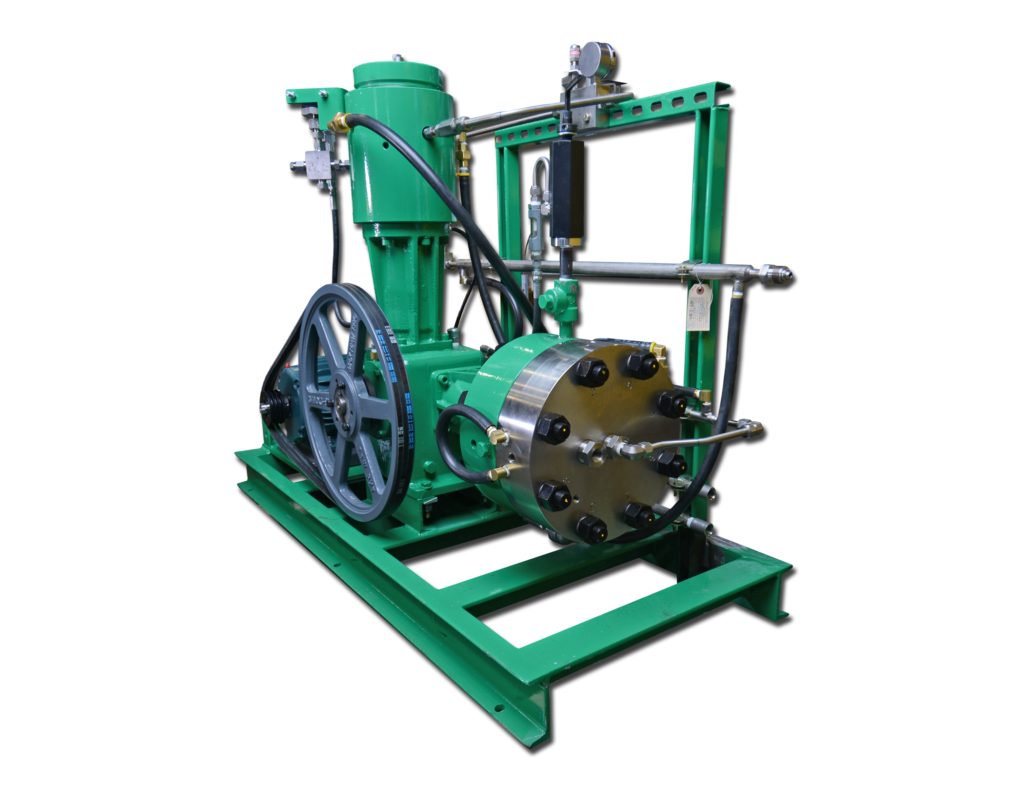

Series 2000 Diaphragm Compressors are for pressures up to 15,000 psig and available in 1 and 2 stage configurations.

- Maximum Working Pressure, 15,000 psi (1,035 bar)

- Maximum Motor Size, 15 hp

- Mounting, L Configuration

- Flanges, 0.5 to 1.0 inch process connection

- Maximum Displacement, 7.1 ft³/min

- Speed Range, 250 to 450 rpm

- Maximum Discharge Temperature, 475°F (246°C)

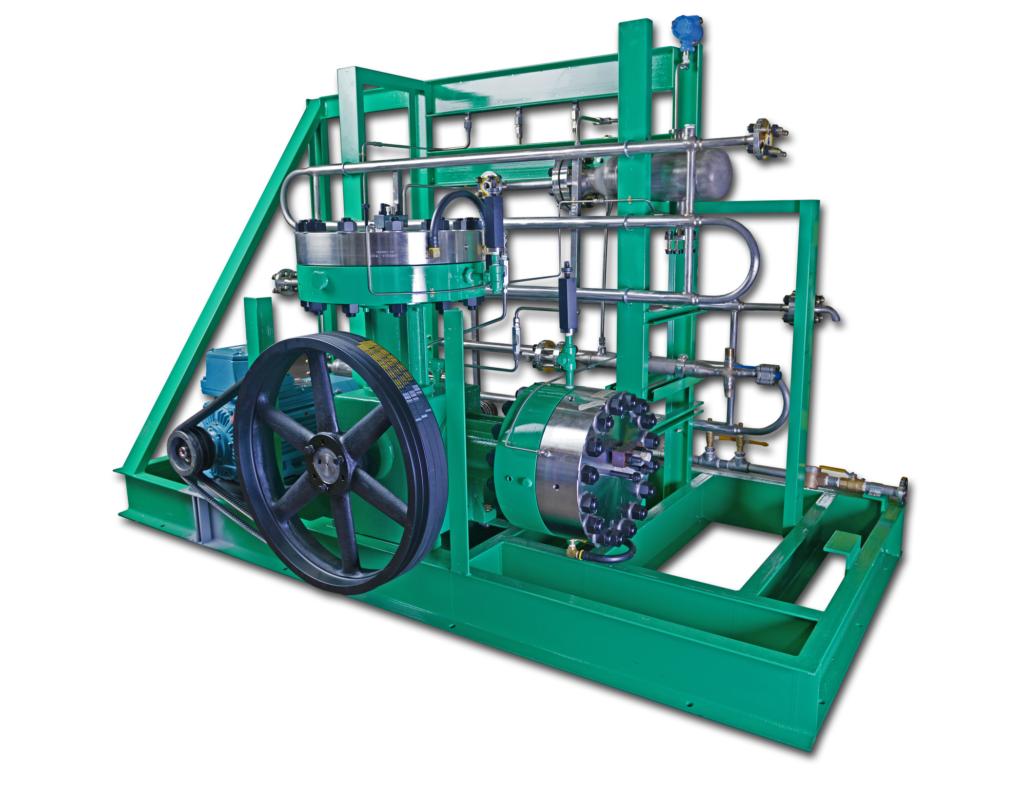

The Series 4000 Diaphragm Compressors are for pressures up to 16,750 psig and available in 1 and 2 stage configurations.

- Maximum Working Pressure, 16,750 psi (1,155 bar)

- Maximum Motor Size, 40 hp

- Mounting, L Type Configuration

- Maximum Displacement, 45.9 ft3/min

- Speed Range, 250 to 400 rpm

- Maximum Discharge Temperature, 450°F (232°C)

- Stroke Length, 4.5 in.

The Series 7000 Diaphragm Compressors are for pressures up to 6,250 psi and available in 1 and 2 stage configurations.

- Maximum Working Pressure, 6,250 psi (431 bar)

- Maximum Motor Size, 200 hp

- Mounting, L or H configurations

- Maximum Displacement, 110.9 ft³/min

- Speed Range 250 to 350 rpm

- Maximum Discharge Temperature 450°F (232°C)

The Series 9000 Diaphragm Compressors are for pressures up to 5,000 psi.

- Maximum Working Pressure, 5,000 psi (345 bar)

- Maximum Motor Size, 250 hp (185 kW)

- Mounting, H configuration

- Maximum Displacement, 146.6 ft3/min

- Speed Range, 250 to 335 rpm

- Maximum Discharge Temperature, 450°F (232°C)